Electrostatic Needle-punched Filter Media

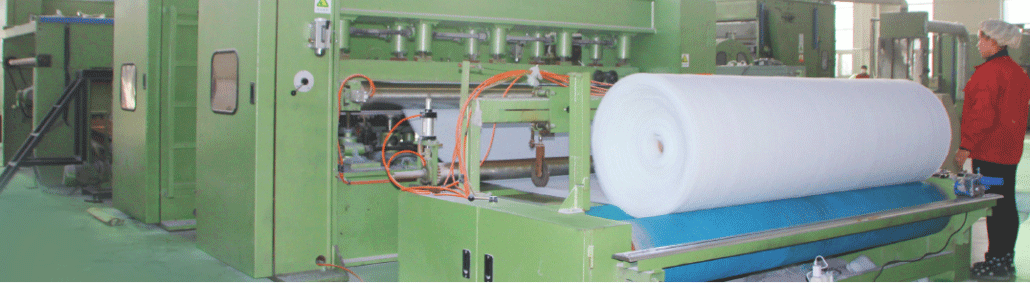

Electrostatic Needle-Punched Filter Media is highly efficient, using a modified polypropylene fiber via a corona-charged electret after needle-punched processing. The process forms a charged electrostatic field and absorbs dust particles from the air into the fiber, in order to achieve high filtration efficiency and superior product performance.

Product Introduction

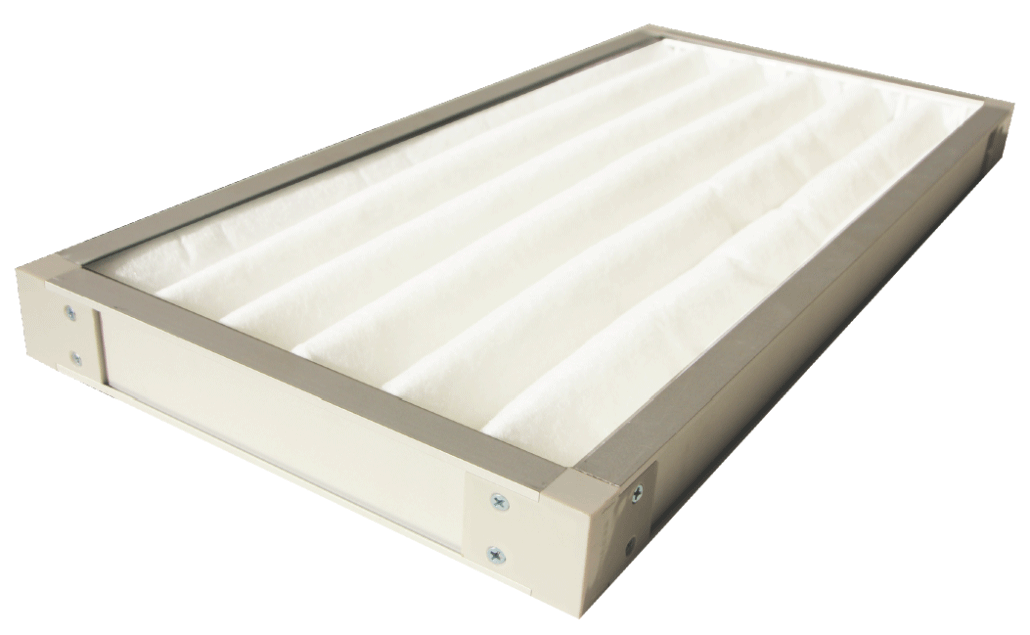

The superior design of the product gives it high-performance values, and means that it captures more dust particles than similar filter media. It offers the advantages of cost-effective integration, enhanced filtration efficiency, less resistance, longer lifespan. Due to its loose structure, it also offers greater dust-storage capacity.

The product can be widely used in domestic automotive air conditioning, home air conditioning, middle-to-high-efficiency air purifiers and high-efficiency respirators. It can also be used with melt-blown material, non-woven material, active carbon particles and multiple effect filter material.

Product Performance

- High efficiency by electrostatic adsorption

-

Electrostatic Needle Punched Filter Media Material has a three dimensional structure, with high porosity and low filtration resistance, leading it to be high performance material.

-

Material has a three-dimensional pinhole, leading to high porosity; it is conducive to dust, giving a greater dust capacity, hence, can be used in variety of applications.

- Material with high porosity is conducive to storing active carbon particles, and can be combined with multiple effect filter material.

Product Technical Specification

| Type | Basic Weight g/m² | Thickness mm | Pressure Drop Pa | Efficiency % |

|---|---|---|---|---|

| HY-JDM-45G | 45 | 1.0 | 1.2 | 50 |

| HY-JDM-60G | 60 | 1.1 | 2 | 65 |

| HY-JDM-80G | 80 | 1.2 | 3.5 | 80 |

| HY-JDM-110G | 110 | 1.6 | 4.6 | 90 |

| HY-JDM-180G | 180 | 2.0 | 6.5 | 98 |