Auto Ceiling Filter Media

Product Introduction

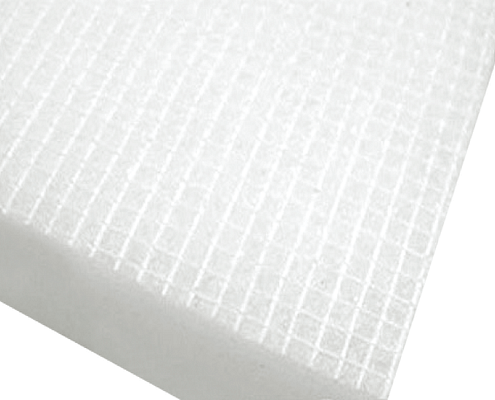

This product uses several different specifications of non-silicon synthetic fiber, which make use of the technology of carding, lapping, thermal-shaping and post-processing. Carding is the disentangling and cleaning of fibers to create a web for processing; lapping refers to the removal of dust to produce a flat sheet (or lap) of fibers; thermal-shaping is the process of heating materials until they are in a pliable form; and post-processing is what takes place after processing.

The product has a progressive structure and a reinforcing polyester scrim or fiberglass mesh adhered to the air-exit side, which not only improves the filter media strength and stiffness but also protects against loss of fibers. It is layered evenly, to increase the accuracy of the filter. High temperature resistance can be reached up to 100°C.

Product Performance

-

Auto Ceiling Filter is mainly used in ventilation systems and on the end of filter equipment. It is especially suitable for spray painting systems and with equipment used for cleaning.

Specification

Material: polyester fibre

standard size: 2m*20m.

The size can be tailored according to the request and requirements of the customer.

Efficiency Grade: F5

Product Technical Specification

| Type | Basic Weight g/m² | Resistance Pa | Thickness mm | Air Permeability mm/s |

|---|---|---|---|---|

| HY-DM-560 | 560 ± 20 | 6 ± 0.1 | 18 ± 2 | 1400 ± 100 |

| HY-DM-600 | 600 ± 20 | 6 ± 0.1 | 20 ± 2 | 1400 ± 100 |